SCROLL THE MOUSE

At Naipu Mining, we pride ourselves on our commitment to innovation and excellence in the mining industry. As a leading ball mill liners manufacturer, we understand the challenges faced by our clients, particularly concerning the performance and durability of mill liners. Our latest advancement, the Composite Mill Liner, is designed specifically to address issues such as intermittent cracking of large semi-self-milling alloy steel liners and slurry leakage. In this article, we will explore the benefits and features of our Composite Mill Liner, showcasing our dedication to improving operational efficiency.

The introduction of the Composite Mill Liner has been a game-changer for many of our clients. Traditional liners often suffer from intermittent cracking, which can lead to slurry leakage and over-grinding within the mill. These issues not only reduce the service life of the lining board but also negatively impact the overall working efficiency of the mill. Our Composite Mill Liner effectively mitigates these problems, providing a robust solution that is well-received by users. As a trusted ball mill liners manufacturer, we are proud to offer a product that enhances reliability and performance in milling operations.

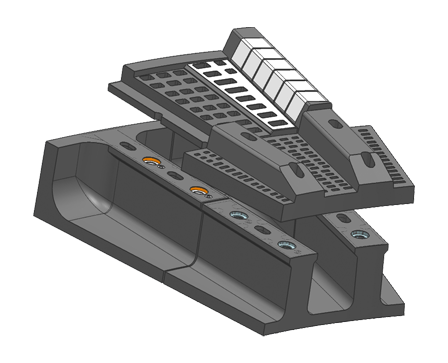

One of the standout features of our Composite Mill Liner is its versatile structure. We offer several configurations, including a metal lifting bar combined with a rubber lining board, a metal lifting bar with a rubber composite lining board, and a composite lifting bar with a rubber composite lining board. This flexibility allows us to customize the liner design according to different working conditions and specific client needs. By tailoring our solutions, we ensure that our clients receive the most effective and efficient liner for their operations, reinforcing our position as a leading ball mill liners manufacturer.

The Composite Mill Liner is not only designed to address immediate performance issues but also to extend the service life of the lining board significantly. Users have reported improved working efficiency, thanks to the unique properties of the materials used in our liners. The combination of metal and rubber components offers superior shock absorption and wear resistance, leading to a longer-lasting product. As a result, our clients benefit from reduced downtime and lower maintenance costs, solidifying Naipu Mining's reputation as a reliable ball mill liners manufacturer.

In conclusion, Naipu Mining is committed to advancing the mining industry through innovative products like our Composite Mill Liner. By addressing common challenges such as intermittent cracking and slurry leakage, we provide our clients with solutions that enhance operational efficiency and extend the service life of their equipment. Our versatile liner structures allow for customization to meet various working conditions, ensuring optimal performance. As a leading ball mill liners manufacturer, we invite you to explore our offerings and discover how Naipu Mining can help elevate your milling operations to new heights of efficiency and reliability. Together, we can navigate the complexities of the mining industry and achieve remarkable results.