SCROLL THE MOUSE

At Naipu Mining, our mill liners have been revolutionizing the grinding processes in the mining industry. These mill liners are not just components; they are essential elements that enhance the overall efficiency and productivity of milling operations.

Mill Liner Materials Mastery

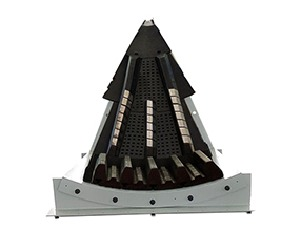

Our team has delved deep into the science of materials to develop high-quality mill liners that outperform. We have perfected the use of rubber lining, which offers unique advantages. The rubber lining we use in our mill liners is a high-grade material with excellent elasticity and abrasion resistance. It acts as a cushion, reducing the impact of the grinding media on the mill shell and thereby increasing the mill's lifespan. Additionally, our composite lining is a result of extensive research and innovation. This composite combines the best properties of different materials, such as the strength of metal and the wear resistance of ceramics. We continuously test and refine our materials to ensure they meet the ever-evolving demands of the mining industry.

Mill Liner Customization Capabilities

We understand that every milling operation is distinct, and a one-size-fits-all approach simply won't suffice. That's why we offer extensive customization options for our mill liners. Our experts work closely with clients to analyze their specific milling requirements. Whether it's a ball mill, semi-self-milling machine, or self-milling machine, we can tailor the mill liner design. For instance, if a client has a particular ore type with specific hardness and grindability characteristics, we can adjust the thickness and pattern of the lining. This level of customization ensures that our mill liners integrate seamlessly into our client's operations and enhance their overall performance.

Mill Liner Durability and Performance

The durability and performance of our mill liners are second to none. Through years of research, design, and testing, we have achieved major technological breakthroughs. Our mill liners have a significantly longer service life compared to traditional liners. The rubber cylinder screen incorporated in some of our mill liners, for example, not only provides efficient screening but also withstands the harsh conditions of the milling process. We maintain a strategic partnership with CITIC Heavy Industry Equipment Co., Ltd. and other leading R&D companies. This collaboration allows us to stay at the forefront of technological advancements and continuously improve the durability and performance of our mill liners. Our mill liners contribute to reduced downtime and increased throughput in milling operations, translating into tangible cost savings and higher profitability for our clients.

Conclusion

In conclusion, Naipu Mining's mill liners are a testament to our commitment to excellence. With our mastery of materials, customization capabilities, and unbeatable durability and performance, we at Naipu Mining are setting new standards in the milling industry. We will continue to invest in research and innovation, leveraging our partnerships and internal expertise to develop even better mill liners. Our goal is to provide our clients with the most reliable and efficient milling solutions, ensuring their long-term success in the highly competitive mining and grinding sectors.