SCROLL THE MOUSE

At Naipu Mining, our trommels have become reliable options in the field of ore separation. These innovative pieces of equipment are designed to meet the complex needs of modern mining operations.

Trommel Design Sophistication

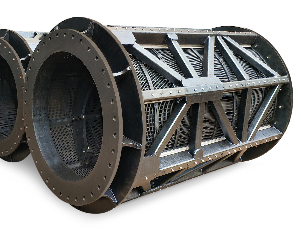

Our trommels are crafted with meticulous attention to detail. The design process begins with advanced software for comprehensive design and analysis. For example, our panel skeleton strength analysis ensures that the trommel can withstand the rigors of continuous operation. The structure of our trommels is optimized for maximum efficiency. They consist of metal frames and rubber screen panels, with our engineers developing various structures to suit specific ore dressing processes. The rubber screen panels are a highlight of our design. They can be customized with different aperture shapes and sizes. The cone-shaped apertures, for instance, are specifically engineered to prevent blocking, ensuring a smooth and uninterrupted screening process. This level of design sophistication allows our trommels to handle a wide range of materials and ore characteristics effectively.

Trommel Operational Efficiency

When it comes to operational efficiency, our role as a trommel screen manufacturer truly shine. They offer high screening efficiency with minimal blockage. This is due to the combination of the well-designed screen panels and the overall structure of the trommel. The simple yet effective design requires less space and is easy to install and maintain. Unlike some other separation equipment, our trommels do not need separate driving equipment or a complex power supply setup. This not only reduces installation costs but also simplifies the overall operation. For example, in a typical mining plant, our trommels can be quickly integrated into the existing setup, minimizing downtime. The ability to select high abrasion-resistant rubber or polyurethane for different applications further enhances operational efficiency, as the trommels can handle abrasive materials without significant wear and tear, maintaining consistent performance over time.

Trommel Adaptability and Support

Our trommels are highly adaptable to different mining scenarios. They are widely used in the classification of materials at the discharge end of various large-scale AG mills, SAG mills, and ball mills. Whether it's for mass classifying, coarse particle and scats removal, pre-classifying, or a combination of these functions, our trommels can be adjusted accordingly. For instance, the pre-classifying self-returning return trommels are perfect for grate mill or AG mill discharge ends, effectively controlling the feed size into the secondary mills. We also provide excellent technical support. Our team of experts is always available to assist with any installation, operation, or maintenance questions. We offer training programs to ensure that our client's staff can make the most of the trommels' capabilities, and we are quick to respond to any technical issues that may arise, ensuring minimal disruption to the mining process.

Conclusion

In conclusion, Naipu Mining's trommels represent a significant advancement in ore separation technology. With their sophisticated design, high operational efficiency, and adaptability, combined with our reliable technical support, they are an invaluable asset to any mining operation. We at Naipu Mining are committed to continuously improving and innovating our trommels, leveraging our technical expertise and industry experience to provide the best possible solutions for our clients. As the mining industry evolves, we will ensure that our trommels keep pace, helping our clients achieve greater productivity and success in their ore separation processes.