SCROLL THE MOUSE

At Naipu Mining, our hydrocyclones have been a cornerstone in the realm of mineral separation. These essential pieces of equipment are widely utilized in the beneficiation processes of non-ferrous and ferrous metal mines.

Hydrocyclone Design Fundamentals

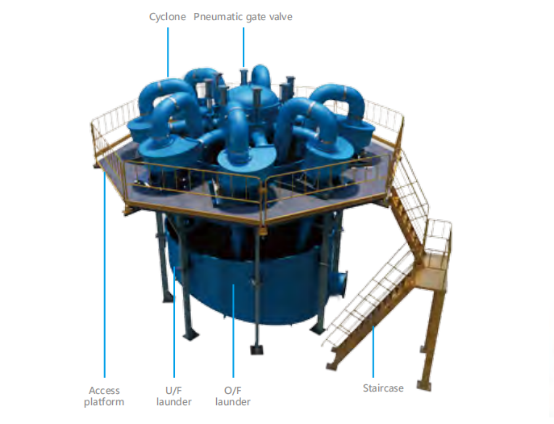

Our team of engineers has focused on perfecting the design of our hydrocyclones. The NPX series, for example, is crafted with a unique inlet design. This design minimizes resistance during the feeding process, which in turn reduces wear and energy consumption. The internal geometry of the hydrocyclone is carefully calculated to ensure a smooth flow of the slurry. The cone and cylinder sections are proportioned in a way that promotes efficient separation. The vortex finder is also a crucial element of our design. It is precisely sized and positioned to direct the overflow and underflow streams with maximum accuracy. This attention to design fundamentals allows our hydrocyclones to handle a wide range of slurry densities and particle sizes effectively.

Hydrocyclone Performance Metrics

When it comes to performance, our hydrocyclone separators excel. They offer a finer separation size compared to many traditional models. This means that we can extract valuable minerals with greater precision. The NPX 838-7 hydrocyclone, as used in the Mongolia copper mine, has shown remarkable results in separating fine copper particles from the slurry. Our hydrocyclones also effectively improve the capacity of single-set equipment. The design allows for a higher throughput without sacrificing separation efficiency. We have been able to reduce short-circuiting, which is a common issue in hydrocyclones. This improvement in classification efficiency leads to a higher recovery rate of metals. For instance, in the Iran copper mine, the gaNPX250-7 cyclone has significantly increased the amount of copper recovered, enhancing the overall economic benefits of the beneficiation process.

Hydrocyclone Maintenance Insights

We understand the importance of easy maintenance for our hydrocyclones. The worn parts of our hydrocyclones have a longer service life. This is due to the use of high-quality materials and advanced manufacturing techniques. The liners, for example, are made from a durable alloy that can withstand the abrasive nature of the slurry. We also provide comprehensive technical support for maintenance. Our experienced engineers can offer guidance on routine inspections and replacement of parts. We supply detailed manuals and training programs to our client's maintenance teams. This ensures that the hydrocyclones can be kept in optimal condition, minimizing downtime and maximizing productivity.

Conclusion

In conclusion, Naipu Mining's hydrocyclones are a testament to our dedication to innovation and quality. With their well-designed structures, outstanding performance, and manageable maintenance requirements, they are an ideal choice for the mining industry. We will continue to invest in research and development to further enhance our hydrocyclones, providing our clients with even more efficient and reliable mineral separation solutions. Our goal is to help our clients achieve greater success in their beneficiation operations and contribute to the growth of the mining sector.