SCROLL THE MOUSE

At Naipu Mining, our flotation rotor & stator has been the cornerstone of efficient mineral separation in the mining industry. These crucial components are designed to meet the most exacting demands of modern beneficiation processes.

Rotor & Stator Design Precision

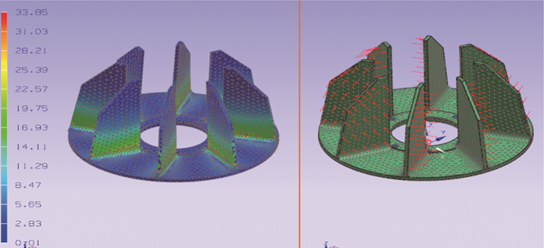

Our team of engineers, in collaboration with BGRIMM, has focused on achieving the highest level of design precision. The flotation rotor & stator for our series KYF and XCF flotation machines. We take into account the slurry flow directions and wear conditions within the flotation cell. The blades are rubber-filled with varying thicknesses, a design innovation that significantly improves the wear resistance of the working faces. After the initial design is conceptualized, we conduct finite element analysis and wear analysis. This allows us to optimize the design and ensure that the rotor and stator operate with the utmost efficiency. The streamlined structure of our products not only reduces resistance but also enhances the overall flotation process.

Material Durability Factors

The durability of our flotation rotor & stator is a result of careful material selection and manufacturing techniques. The metal skeleton inserts are fabricated using advanced flame-cutting for precise material preparation. These inserts are then assembled and welded under strict welding procedure specifications. They are tested with a dynamic balancer to guarantee their strength and equilibration performance. The wear resistant rubber used in combination with the metal skeleton is of the highest quality. It is selected for its ability to withstand the abrasive nature of the slurry and the corrosive environment of the flotation cell. This combination of materials ensures that our rotors and stators have a long service life, reducing the need for frequent replacements and minimizing downtime.

Performance Optimization Strategies

We have developed several strategies to optimize the performance of our flotation rotor & stator. The high equilibrium precision of our products results in smooth operation. This, in turn, maximizes the flotation efficiency. We continuously monitor and adjust the manufacturing process to ensure that each rotor and stator meets the required performance standards. Our technical team also provides on-site support and advice to our clients. They can help with the installation and commissioning of the flotation equipment, ensuring that the rotor and stator are operating at their peak performance. Additionally, we offer training programs to our client's operators, teaching them how to maintain and optimize the performance of the equipment over time.

Conclusion

In conclusion, Naipu Mining's flotation rotor stator are essential for efficient separation in mining operations. Through our precise design, durable materials, and performance optimization strategies, we have been able to enhance overall beneficiation outcomes and productivity. We are committed to continuous innovation and improvement, leveraging our technical expertise and industry experience. Our goal is to provide our clients with the most reliable and efficient flotation rotor and stator solutions, enabling them to achieve greater success in their mining operations.