SCROLL THE MOUSE

When working in industries like mining, construction, and chemical processing, dealing with slurries—mixtures of water, chemicals, and solid particles—can be a challenging and costly task if not managed efficiently. The right equipment, specifically slurry pumps, can make a world of difference in terms of operational efficiency and cost management. In this article, we’ll explore how partnering with a trusted slurry pump supplier can directly influence the success of industrial processes and ensure long-term, sustainable operations.

Why Slurry Pumps Are Integral to Industry Operations

Slurry pumps are not your typical pumps. They are engineered to withstand extreme wear and tear caused by abrasive, thick, and often corrosive mixtures. Industries such as mining, construction, and wastewater treatment need slurry pumps to effectively transfer slurries from one point to another without compromising on performance. Standard pumps fail to perform in such tough conditions, which is why slurry pumps are designed with durability and reliability in mind.

For industries operating in harsh environments, partnering with an experienced slurry pump supplier is crucial. Naipu Mining, as an established supplier, provides robust solutions that are optimized for various industrial applications. With the right pump, industries can minimize downtime, reduce maintenance costs, and avoid the costly consequences of pump failure.

The Crucial Role of Material Selection in Pump Efficiency

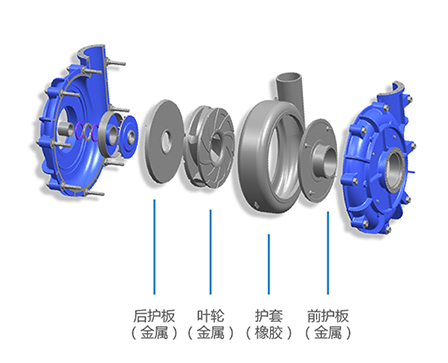

Not all slurry pumps are created equal, and the material used in manufacturing them plays a pivotal role in determining their lifespan and performance. Slurries come in different forms, from fine, low-abrasion mixtures to coarse, high-abrasion materials. Choosing the right pump material ensures that the pump can handle the specific demands of the slurry without unnecessary wear or breakdown.

Naipu Mining offers a variety of material mixes for slurry pumps, allowing industries to select the perfect match for their specific needs. For example, our R (Rubber Impeller + Rubber Sheath + Rubber Shield) mix is tailored for less aggressive slurries with medium fine particles, offering great abrasion resistance and performing well in low to medium head applications. On the other hand, the M (Metal Impeller + Metal Sheath + Metal Shield) mix is built for handling high temperatures and slurries with mineral oils, making it ideal for tough industrial environments.

For those dealing with a mix of conditions, Naipu Mining’s MR (Metal Impeller + Rubber Sheath + Rubber Shield) combination brings the best of both worlds: metal durability for handling rough conditions and rubber to withstand abrasions. This hybrid option is perfect for industries requiring both flexibility and strength, like in high-lift delivery and semi-self-grinding discharge scenarios.

Maximizing Performance Through Expert Slurry Pump Selection

When selecting a slurry pump, it's essential to consider not just the material but the design and functionality of the pump. A supplier with deep expertise in the field, like Naipu Mining, can guide you in choosing the right pump design and material mix for your specific needs. For example, our NZJV vertical slurry pump is designed for optimal performance in abrasive and corrosive environments, making it perfect for industries like mining that often deal with heavy-duty materials.

The impact of working with a knowledgeable supplier goes beyond simply purchasing equipment. By ensuring that you are equipped with the right slurry pump, you not only optimize your operations but also extend the life of your equipment and reduce the risk of costly downtime. It’s about investing in a solution that will pay off in efficiency, safety, and long-term cost savings.