SCROLL THE MOUSE

In the mining industry, flotation cells play a crucial role in separating valuable minerals from waste material. The efficiency of flotation cells largely depends on the quality of the Flotation Rotor & Stator used in the process. As a leader in mining solutions, Naipu Mining offers high-quality, durable, and efficient flotation rotor and stator products, designed to optimize flotation performance. This article will explore the importance of flotation rotors and stators and how Naipu Mining ensures the best results for mining operations.

The Role of Flotation Rotor & Stator in Mining

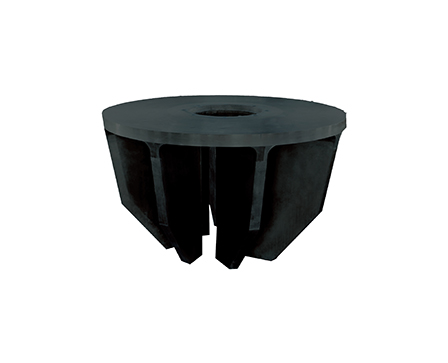

The flotation rotor and stator work together in flotation machines to create the necessary agitation and air distribution required for the flotation process. The rotor introduces air into the slurry, while the stator helps to direct the flow of the slurry for effective mineral separation. Both components are integral to the flotation cell’s performance and must be designed for durability and wear resistance.

At Naipu Mining, we leverage the advanced design capabilities of the Beijing Research Institute of Mining and Metallurgy, combined with superior materials and cutting-edge manufacturing technology, to produce high-performance flotation rotor and stator solutions. The quality of these components directly impacts the efficiency of the flotation process, leading to better mineral recovery and reduced downtime.

Custom Design and Optimization for Maximum Durability

One of the key features of Naipu Mining’s flotation rotor and stator products is their custom design, tailored to meet the specific needs of various mining operations. The rotor and stator are designed with a focus on slurry flow directions and wear conditions within flotation cells. By optimizing the blade rubber thickness—whether thicker or thinner—we can enhance the wear resistance of both the rotors and stators. This ensures that the working faces of these components remain effective and durable even under extreme conditions.

Before finalizing the design, our team conducts finite element analysis and wear analysis. This thorough process helps optimize the design to ensure that it delivers maximum efficiency and longevity. The final solution is always fine-tuned to provide the best flotation performance.

High-Quality Manufacturing for Reliability

The manufacturing of flotation rotors and stators involves a precise and methodical process. Naipu Mining utilizes metal skeleton inserts, which are fabricated with advanced flame cutting techniques for material preparation. The assembly and welding are carried out under strict welding procedure specifications to ensure structural integrity. Once the rotor and stator are assembled, they undergo a dynamic balancing process to inspect their strength and equilibration performance.

This rigorous approach to manufacturing guarantees that Naipu Mining flotation rotor and stator products meet the highest standards of quality, ensuring maximum efficiency and reliability in flotation operations.

Conclusion

As a renowned flotation stator and rotor manufacturer, Naipu Mining is committed to providing mining companies with durable, high-performance components designed to optimize flotation processes. Our advanced design and manufacturing techniques ensure that each flotation rotor and stator is optimized for wear resistance, strength, and efficiency. By choosing Naipu Mining, you are investing in quality and reliability, ensuring better mineral recovery and more efficient mining operations.