First-class design concept, Strong R&D capability

SCROLL THE MOUSE

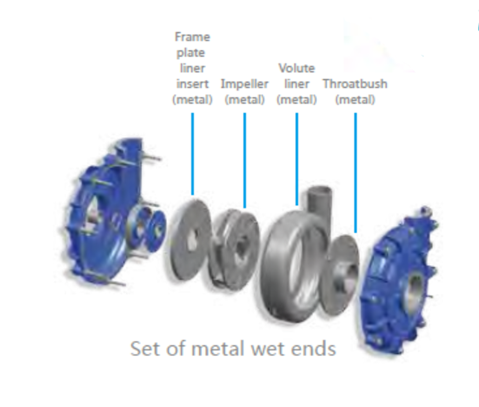

NZJAH series slurry pump is a general-purpose heavy-duty slurry pump, which is a kind of horizontal centrifugal pump. The structure adopts horizontal double shells, in which the inner shell is an wet vulnerable part, which needs to be replaced periodically. High-chromium alloy metal or rubber materials can be selected. The product is relatively simple in structure, reliable in operation, and long in service life of the wet parts, especially suitable for medium and high concentration slurry transportation.

1.Overview

NZJA series slurry pumps are designed for heavy duty systems that convey abrasive slurries so as to create the best value for the client.

The NZJA Heavy duty pumps are specifically designed for the most severe slurry applications such as SAG mill and Ball mill cyclone feed plus waterflush crushing in process plant. The NZJAH range of pumps easily manages large size particles in dense abrasive slurries and suitable for use as slurry transfer pumps in arduous applications such as gravel dredging or coarse coal cyclone feed.

2.Design

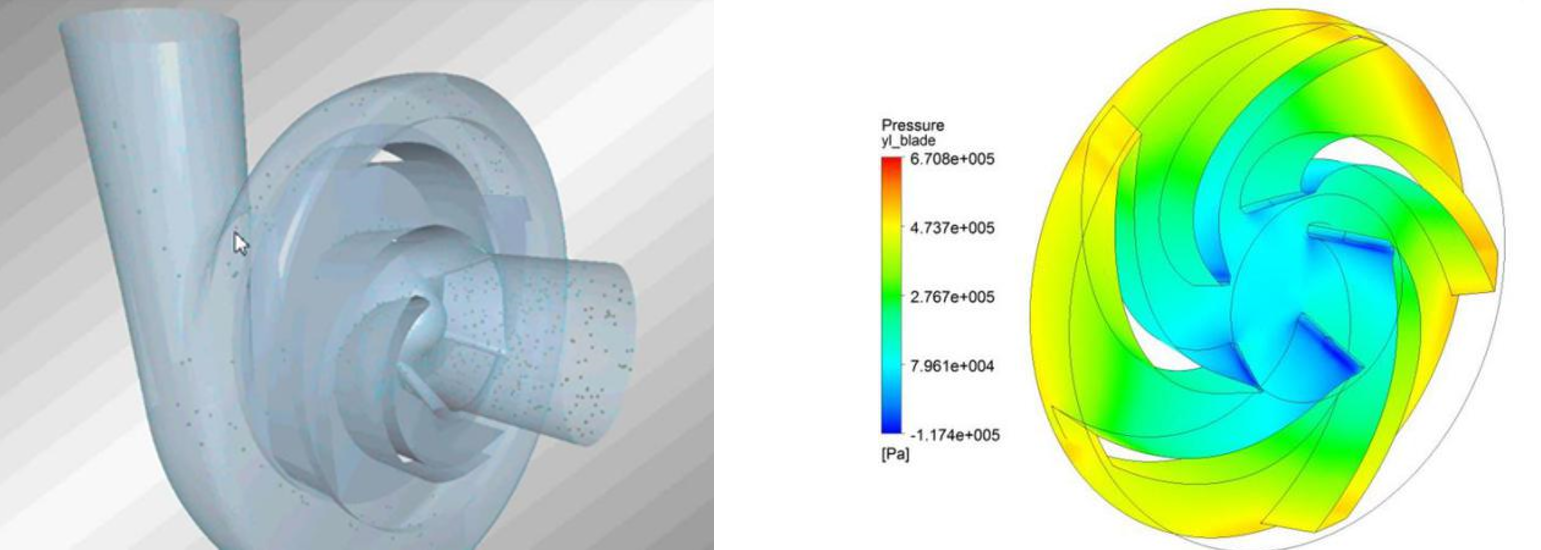

The NZJA Heavy duty pump extended wear life and had a significant reduction in power consumption costs through the state of the art hydraulic design which has been designed and developed using Computer Fluid Dynamic Analysis, as well as extensive real world testing.

Naipu runs its own material research and test center, focusing on the development and application of a variety of rubber and polyurethane materials, in combination with technical exchange and cooperation with universities and research institutes in China.

Rubber preparation technology with liquid-phase method has been applied and various natural rubber compounds have been developed for slurry pumps. High grade latex originated in Southeast Asia is used, in combination with fully dispersed rubber accelerant, to produce quality natural rubber with features of:

- high resilience

- high tear strength

- ultraviolet resistance

- aging resistance

Wet end parts in a slurry pump made of which are:

- abrasion resistant, especially against the abrasion of coarse particles of certain sizes

- weather proof, with a long shelter life

- corrosion resistant, well applicable to general acid or basic conditions

- Advance hydraulic design offers high efficiency and best energy-saving effect

- Excellent material selection offers best service life under different operating conditions and lower operating costs

- Simple structure, easy maintenance and operation

- Multiple ways of installation and arrangement are available

- Eight discharge positions are available by rotating the angles

- Various bearing assemblies are available to match installed power

- Options of different shaft seals are available for different operating conditions

- Multiple modes of material configurations

- A wide span of performance, suitable for application on most posts for transferring slurries

4,Specifications

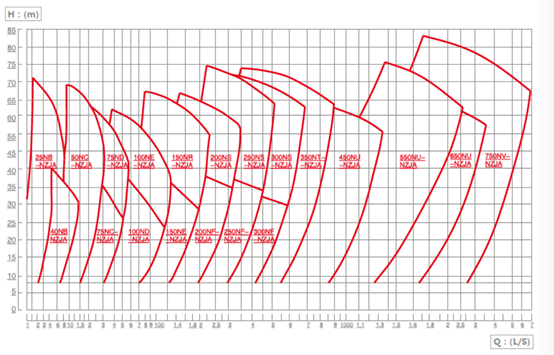

When the model selection is conducted for a NZJA Series slurry pump, the clear water performance curve table for a pump shall be referred to, and the coefficient for the flow range selected is as follows:

Note:

1. These are performance curves for clear water.

2.The chart just serves as a reference for preliminary model selection.

5. Cases

Erdente, Mongolia,550-NZJA

Mirado copper mine in Ecuador, 650-NZJA

Jiangxi Copper Group 450NZJA slurry pump

TISCO 450NZJA slurry pump

Peru 650NZJA slurry pump