First-class design concept, Strong R&D capability

SCROLL THE MOUSE

The rubber composite pipes produced by Naipu mining machine are mainly divided into two series: steel rubber composite pipes and rubber hoses. It is mainly used for pipeline transportation systems that require wear resistance and corrosion resistance, such as mine slurry and tailings transportation.

Pipes& hose

Rubber composite pipes produced by Naipu are in two series of rubber lined steel pipes and rubber hoses, which are used in wear-resistance and corrosion resistant pipelines transferring slurry or tailing.

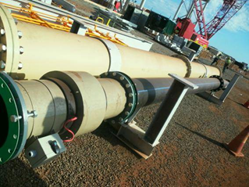

1.1Rubber lined steel pipes

1.1.1Structure of rubber lined steel pipe

Rubber lined steel pipe makes use of ordinary steel pipe as its skeleton with abrasion, corrosion and heat resistant rubber lining inside, both of which are combined with high performance adhesives through special technology. With combined advantages of both steel and rubber materials, this composite pipe becomes a prior selection in piping systems in modern mining operations.

1.1.2Features

Wide range of application

Super impact resistance

Wear Resistance

Corrosion Resistance

Long Service life

Reusable

Easy installation and maintenance

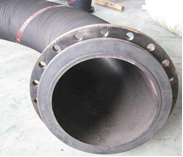

1.2Rubber Mining hose

1.2.1Structure of rubber mining hose

Rubber mining hose for conveying slurries is compositely structured with multi-layer rubber and steel wire skeleton and non-metal reinforcement layers through special technology. The innermost wear layer is made of premium natural rubber emulsion and is resistant to slurry abrasion. Naipu designs and produces a variety of special pipes to suite special duties and condition.

1.2.2Features

Reliability,impact resistance

Abrasion and corrosion, aging resistance

Wide range of Temperature, from 50 to 95 Degree Celsius

Anti Static pressure, high tensile resistance

Slow scaling, energy saving, easy mounting

Steel rubber composite pipe case

CITIC Pacific Australia SINO Iron Ore Project φ50-φ900 мм стальные резиновые композитные трубы