Professional technical and after-sales service team

SCROLL THE MOUSE

Project Profile:

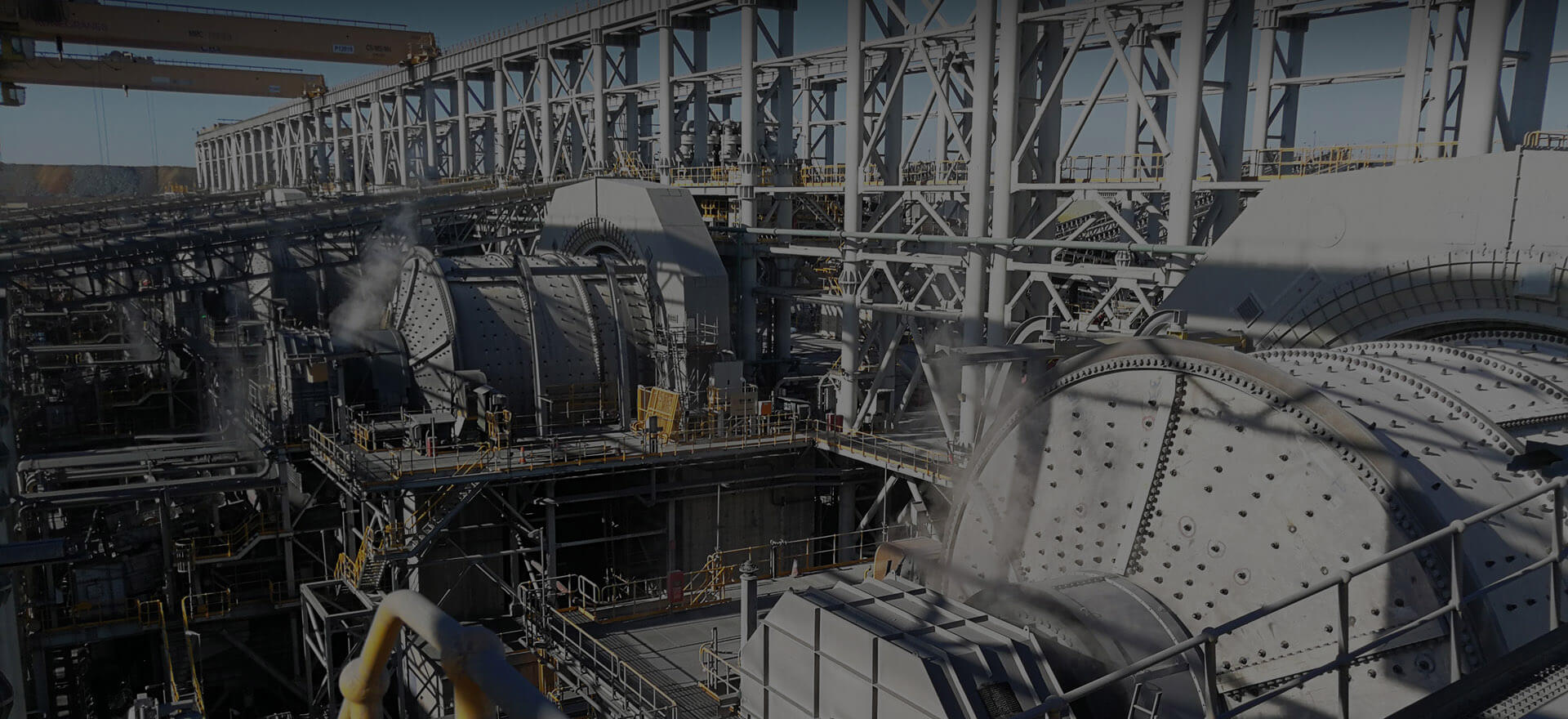

The grinding and classification circuit adopts an SABc process, consisting of a SAG mill + ball mill + pebblecrusher conliguration.The grinding equipment includes one p8.53 x4.27 m semi-autogenous (SAG) mi.l andone φ6.2x 11.5 m overflow-type ball mill.

Performance:

The first set of high-alloy forged liners supplied by Naipu was installed on May 25, 2025 and replaced onOctober 2, after 131 days in operation.As this was the client's first use of forged liners, the design main-tained the same dimensions as the original cast metal liners, which limited the liner's designed servicelife.The second-generalion liners are designed for a service life of 2 million tons of ore, double that of thecast Cr-Mo steel liners.They are currently in production and scheduled for installation in early 2026.