Professional technical and after-sales service team

SCROLL THE MOUSE

Project Profile:

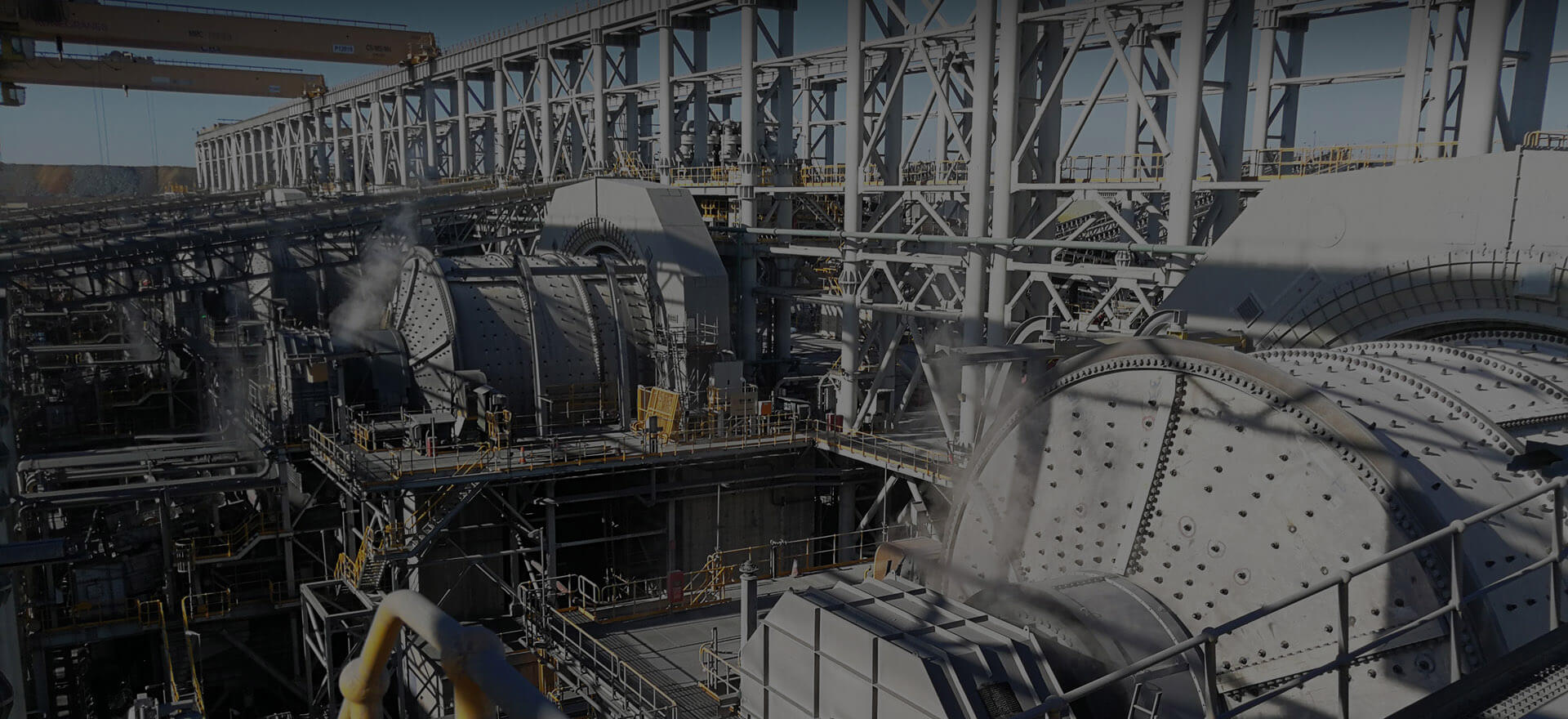

The grinding and classification circuit at this concentrator consists of one $7.5m x 3.2m semi-autogenous mil, one p5.5m x8.5m ball mill, and two sets of 8 x FX660 hydrocyclones, forming a closed-circuit grinding process. According to research, themill was originally equipped with cast chrome-molybdenum steel shell liners, which had a service life of approximately 105days. Through continuous improvements by other liner manufacturers, the maximum service life of cast chrome-molybde.num steel shell liners has now reached 126 days.

Post-Modification Performance:

The first set of high-alloy forged liners supplied by Naipu was installed on September 9, 2024 and replaced onApril 29, 2025, after 232 days in operation. Replacement was due to local wear near the grate plate at thedischarge end. Thickness checks and 3D scan data showed that liners near the feed end could have run foi100+ more davs.

The second set of high-alloy forged liners was installed on May 3, 2025. As of the maintenance inspection onOctober 23, 2025, it has operated for 163 days, processing a cumulative total of 1,415,610 tons of ore. Themill shell liners remain in service, with a specified service life of 10 months.